Pushing forward Aerospace interiors with Advanced Fastening Technologies

Advancing Aerospace Engineering with Specialized Fastener Solutions

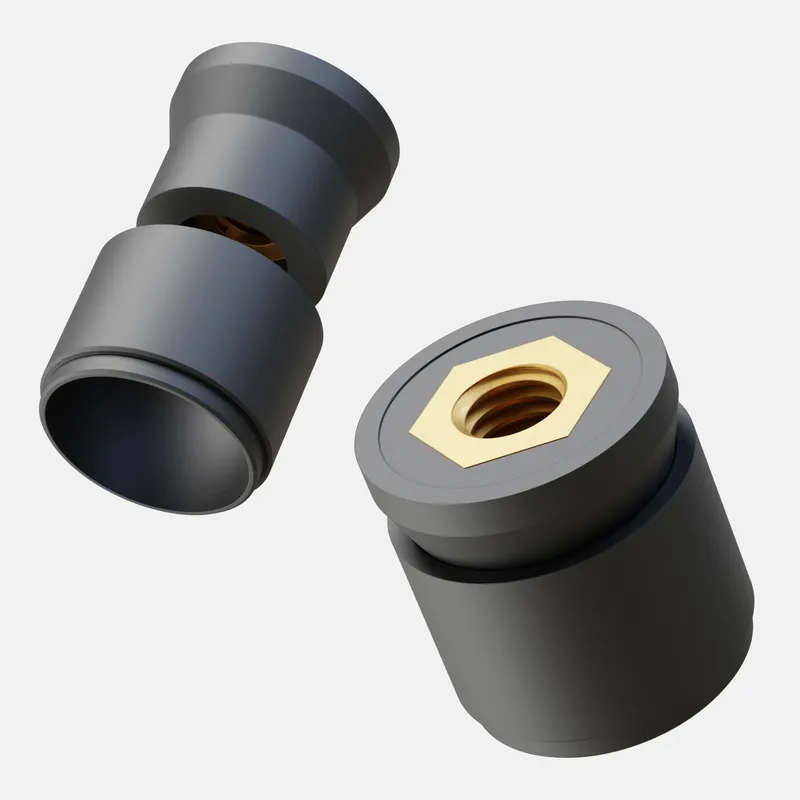

In the dynamic world of aerospace manufacturing, MultiMaterial-Welding AG plays a crucial role with its specialized fastening solutions. We focus on developing innovative fastening solutions to replace traditional methods like gluing or insert potting in primary aerospace structures. Using advanced ultrasonics methods, our technologies are specifically designed for complex sandwich structures with honeycomb and foam core materials or thermoplastic trimmed part and lining.

This approach not only enhances the reliability and durability of aerospace components but also offer a more efficient and precise alternative to conventional fastening methods. Our commitment lies in advancing aerospace engineering with technologies that elevate both efficiency and safety in interior application.

We have what you are looking for

Our technology is applicable to a wide variety of assembly parts.

Click on the parts to find out more.

Plastic window covers

Robust fastening systems ensure plastic window covers are securely attached, enhancing safety and clarity in aerospace environments.

go to product

Galleys / kitchen

Secure fastening solutions maintain the integrity and functionality of galleys and kitchen areas in aerospace applications.

go to product

Interior floor panels

Durable fastening techniques ensure interior floor panels remain firmly anchored, contributing to cabin stability and passenger comfort in aerospace applications.

go to product

Overhead compartments

Efficient fastening solutions keep overhead compartments securely in place, ensuring passenger convenience and safety.

go to productWe have what you are looking for

Our technology is applicable to a wide variety of assembly parts.

1. Galleys / kitchen

2. Plastic window covers

3. Interior floor panels

4. Overhead compartments

Facts & stats

Fast processing time

Designed for quick installation in about 1 second, eliminating the need for adhesive, thereby streamlining the assembly process

Weight reduction

Our advanced fastening solutions can contribute to a weight reduction of up to 40% in aerospace components, leading to improved fuel efficiency

Quality control

MM-Welding® technology allows zero defect and reduced material waist through a fully controlled and precise process

Featured products

Customer voices

Discover how our customers' stories show the real impact of our innovative, flexible, accountable, and teamwork-driven fastening solutions on their success.

"Incorporating MultiMaterial-Welding's technology in our parts production, particularly airplain window frames, has greatly improved both the efficiency and reliability of our products, marking a significant advancement in aviation manufacturing."

Patrick Gygax

Plastika Balumag AG

Do you have any questions?

Let us know how we can support you.

We are looking forward to it.